Think about what happens when you try to stick a label on a dirty or uneven surface. If there’s dust, the sticker doesn’t stay in place. If the surface is too rough, the edges lift, and it falls off over time. Now imagine trying to use your hands to climb up a glass-smooth window—literally impossible, there’s no grip. Both ideas apply to a garage floor coating. For it to hold, the concrete underneath needs just the right texture—rough enough to grab onto, but not so rough that it weakens the finish.

The Range of Concrete Surface Profiles

The technical term for this texture is the Concrete Surface Profile (CSP). Smooth concrete has a CSP rating of 1, while very rough surfaces rank closer to 10. A good garage floor coating needs a CSP in the 3–4 range, hitting our very own version of the Goldilocks zone.

Too smooth and the concrete coating won’t bond. Too rough and you’re creating problems you don’t need.

How Not to Prep

There are many ways to change how concrete feels underfoot. Acid etching and water jetting don’t cut it—they leave the surface too smooth and increase the risk of peeling in high-traffic areas. On the other extreme, sandblasting or rotomilling create too much texture, which isn’t necessary for most garages.

Propane Grinders

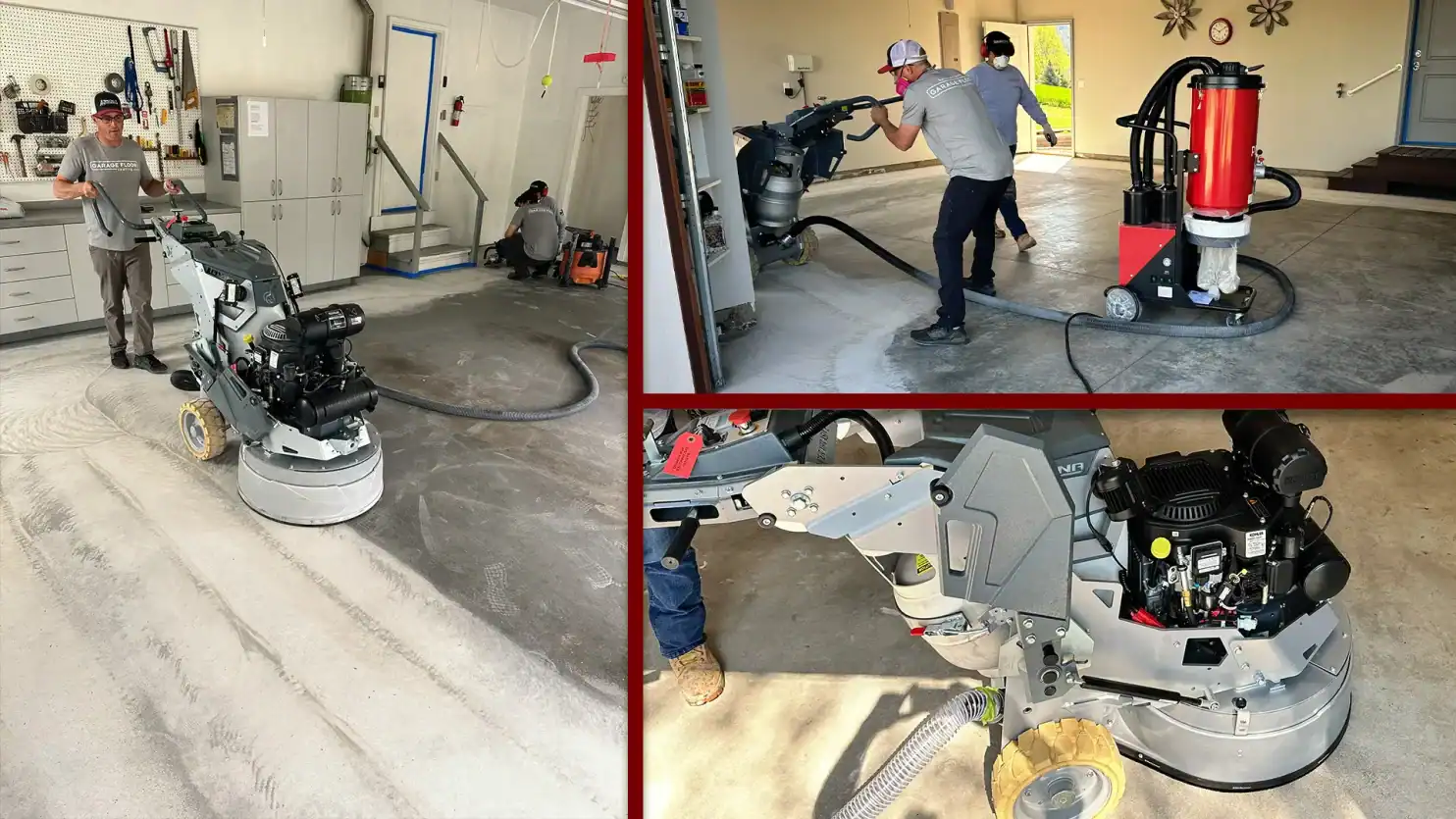

Grinding is the solution that gets it right. Propane grinders, in particular, provide enough power and speed to prep a floor evenly and efficiently. Unlike electric grinders, which are slower and less powerful, propane models can deliver the correct CSP consistently. This step is what sets professional installation apart from DIY kits.

Propane grinders sound a little intense, sure, but they’re our choice tool for a quality garage floor coating job, hands down. They’re actually typically the safer option, as you’re not dragging around extension cords, the emissions are near-zero so they’re fine for small spaces indoors, and they actually do the job correctly.

Why New Jersey Homeowners Should Care

In New Jersey, where garages see plenty of seasonal changes—wet snow, salt, and mud in the winter, humidity in the summer—bonding strength is crucial. A properly prepped surface ensures that the garage floor coating resists peeling, cracking, and damage from the constant cycle of weather and vehicle traffic.

The Bottom Line

If you’re investing in a garage floor coating, make sure the contractor talks about concrete preparation. Ask how they achieve the right surface profile, and whether grinders are part of the process. In the end, concrete prep is the foundation for a floor that lasts.