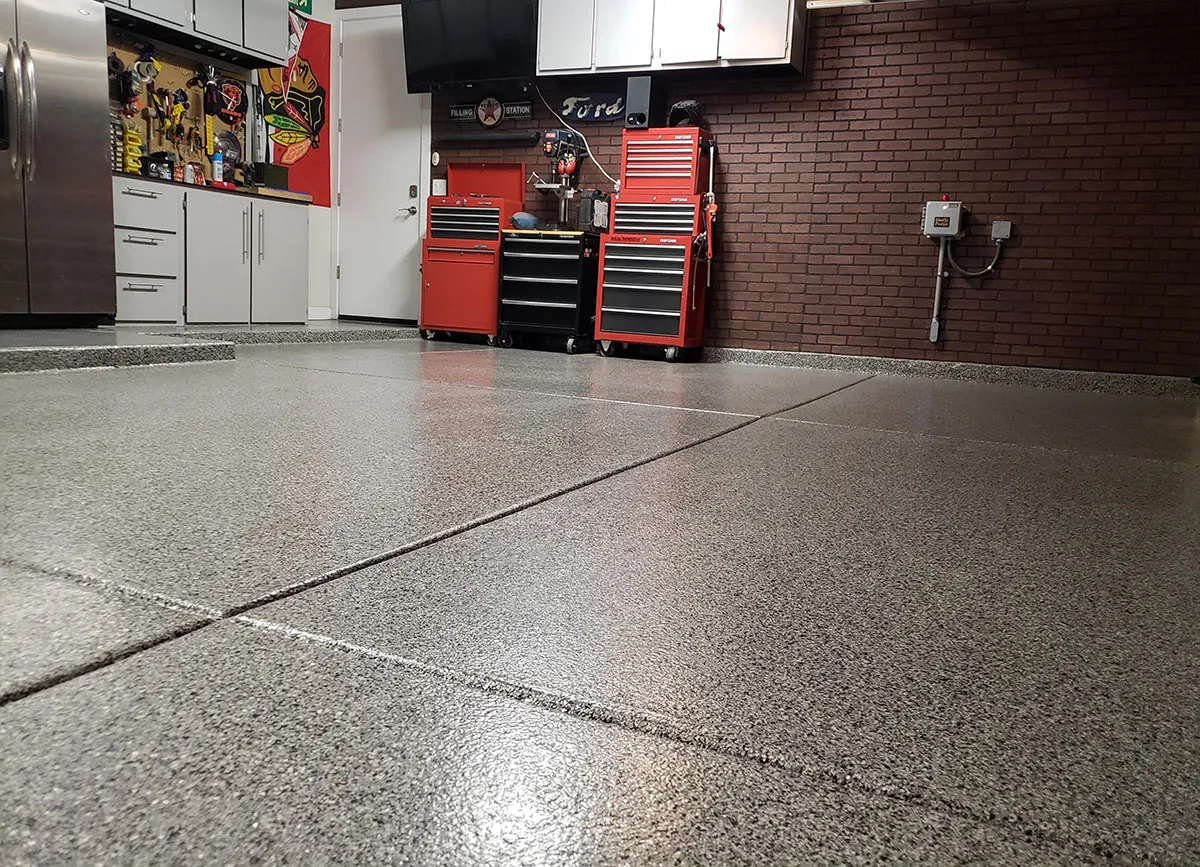

If your garage doubles as a workshop, your floor needs to do more than just sit there. In homes across New Jersey, bare concrete might be the default—but it’s also one of the biggest obstacles to a safe, functional workspace. That’s where professionally-installed, hybrid epoxy and polyaspartic garage flooring from Garage Floor Coating of New Jersey comes in.

1. Cracks and Chips from Dropped Tools

Concrete is hard—but not invincible. Drop a wrench or a saw, and it’s likely to chip or crack. GFC of NJ’s garage flooring is engineered for impact resistance, meaning it can handle the hits without permanent damage. No more eyesores, no more hazards.

2. Permanent Stains from Paints, Oils, and Solvents

Workshops tend to get messy. But when chemicals soak into your floor, they leave lasting damage. But our floors provide extreme chemical resistance, so even if you spill oil, wood stain, or cleaning solvents, you can wipe it up without worry.

3. Unsafe Conditions from Slips and Dust

Between sanding, sawing, and spraying, workshops are full of slip risks. Poorly coated concrete (with inadequate or no anti-skid) gets slick fast, especially when dusty or wet. GFC of NJ floors feature an anti-skid surface that helps keep your footing secure—whether you’re hauling equipment or sanding a cabinet.

4. Moisture That Sneaks Up from Below

New Jersey’s wet seasons can push moisture right through a poorly-installed garage floor coating (one without a moisture vapor barrier), damaging the coating system that you paid good money for. All GFC of NJ’s garage floor coating systems include a thick, moisture mitigating epoxy base coat. It acts as a moisture vapor barrier, helping prevent water vapor and high hydrostatic pressures from delaminating your workshop floor.

5. Tire Marks from Hot Vehicles

Hot tires are brutal on untreated floors. One quick drive can leave dark, rubbery marks that never come out. GFC of NY’s dual, highly cross-linked, 100%-solids polyaspartic topcoats prevent hot-tire transfer, so your floor stays as clean and sharp as the day it was installed.

The GFC 2-Day System: Built to Last

Garage Floor Coating of New Jersey uses a professional 2-day installation system—never rushed, never cut short. On Day 1, following concrete preparation, we install a thick, 100%-solids moisture-mitigating epoxy base coat. We broadcast your selected flake blend into this primer coat in a thick, full flake spread. On Day 2, after a full day of concrete penetration, we return to apply two separate layers of our 100%-solids polyaspartic topcoat for strength, UV protection, and chemical durability. It’s the right system for serious garage workshops.

If you’re tired of working around floor problems, it’s time for a real solution. Contact Garage Floor Coating of New Jersey and upgrade your garage flooring today.