When you start comparing garage flooring systems, you’ll see a lot of technical terms—many used loosely or without explanation. This quick dictionary breaks down what each term actually means so you can make informed decisions when evaluating installers and products.

Epoxy Coatings

A two-part material created by mixing a resin and a hardener. Epoxy cures into a dense, strongly adhesive layer that bonds tightly to concrete, which is why it’s used as the direct-to-concrete primer and broadcast coat in professional garage flooring systems. Its strength and thickness give the floor its core durability.

Moisture Mitigation

Concrete constantly releases moisture vapor, and without moisture mitigation, coatings can peel, bubble, or delaminate—even indoors. Proper moisture mitigation requires the use of a thick, 100%-solids moisture-mitigating epoxy primer coat; it forms a moisture vapor barrier beneath the coating system. 2-day installations include this step; 1-day systems (in pursuit of speed) commonly skip it.

Concrete Paint

A thin, cosmetic product meant only to color the concrete surface. Because it doesn’t chemically bond to concrete and can’t tolerate hot tires, moisture, or road salts, concrete paint typically wears away quickly. It is not a substitute for a true garage floor coating.

Polyaspartic

A UV-stable, rapid-curing clear topcoat that protects the underlying epoxy and flakes. Polyaspartic is exceptionally resistant to stains, chemicals, and abrasion, which makes it ideal for the final layer of a professional system. Despite some marketing claims, polyaspartic is not meant to replace the moisture-mitigating epoxy primer coat.

Polyurethane

Another type of clear coat used in some flooring systems. While durable, polyurethane generally offers lower UV stability and chemical resistance compared to polyaspartic—an important distinction for garages exposed to sunlight or harsh conditions.

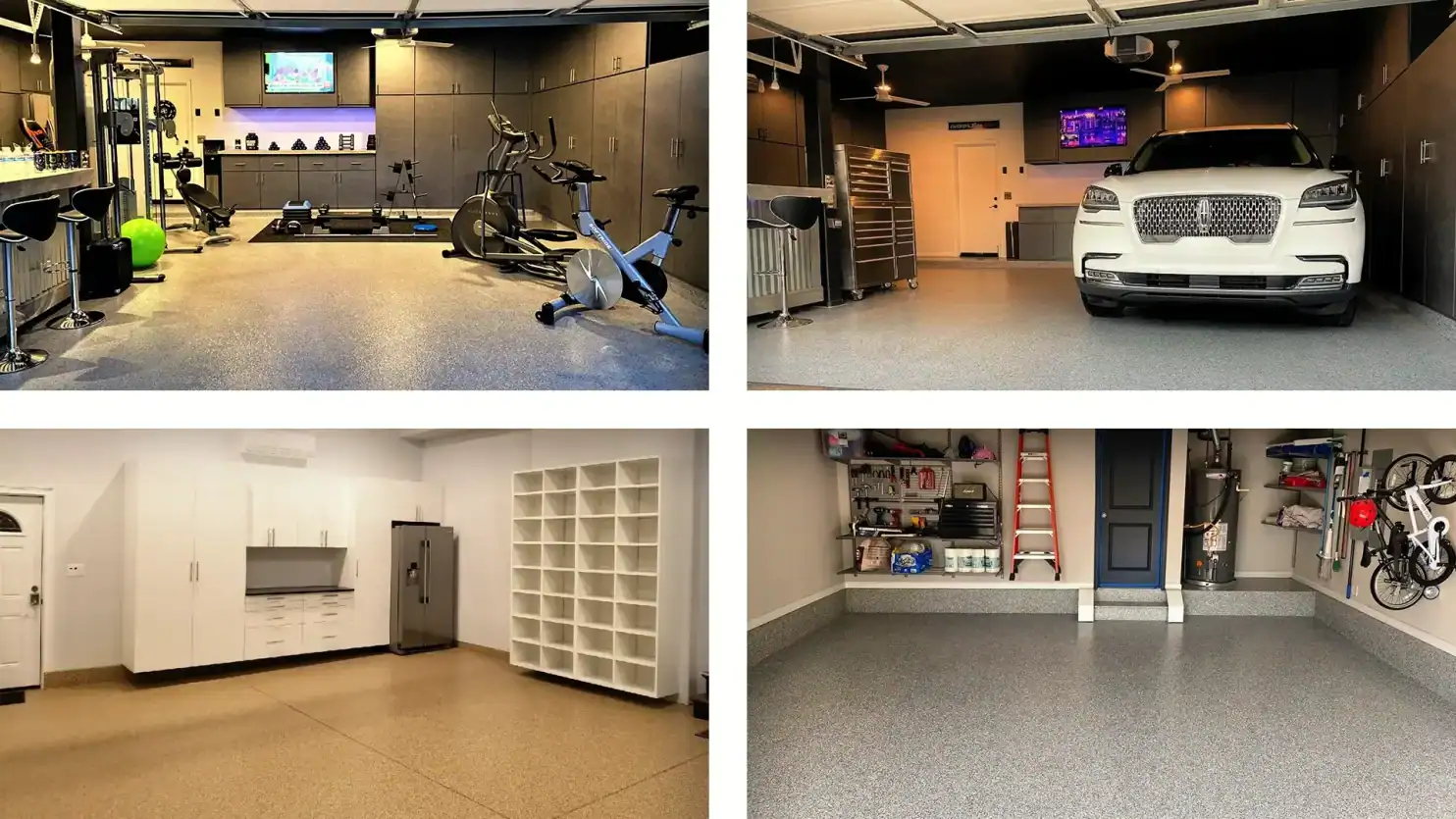

Flake/Full-Flake

In a flake epoxy system, colored polyvinyl acetate (PVA thermoplastic) and/or mica mineral flakes are broadcast into the wet epoxy layer to add traction, depth, and visual texture. A full-flake installation covers the entire surface, creating a thicker, more uniform finish that improves durability and appearance.

Garage Floor Coating

A multi-layer system built from a moisture-mitigating epoxy primer, full-flake coverage, and 100%-solids polyaspartic topcoats. Together, these layers create seamless, long-lasting garage flooring engineered to perform far better than DIY or paint-based alternatives.

Want garage flooring built for New Jersey’s climate? Garage Floor Coating of New Jersey delivers premium systems designed for long-term performance. Request your free quote today.